FIRED HEATERS & FURNACES

CANTY's high temperature camera systems are installed on Fired Heaters and Furnaces to obtain video during operation. This video is fed into CANTY's Smart Tube software to monitor TMT's, identify hot spots, and even track the position of individual tubes as they shift over time.

FIRED HEATERS & FURNACES

FLARE CAMERAS

The CANTY UltraTemp™ is a vision-based camera system used with the CantyVision™ to monitor the flares inside an enclosed ground flare unit.

FLARE CAMERA

FREE WATER & TSS IN LNG

CANTY manufactures analyzers designed for the inline measurement of the concentrations and particle size and shape distributions of water and total suspended solids (tss) in LNG lines.

FREE WATER & TSS IN LNG

FUELS & BIODIESEL

CANTY specializes in many FUEL applications. Some of the applications include water / solids in fuel monitoring.

FUELS / BIODIESEL

JET FUEL

Using the ASTM D8049 & D7596 methods, the CANTY Inflow™ is a vision-based camera system used with the CANTY Vector System image processor for JET FUEL concentration and size measurement in a lab environment / at-line (Short Loop Sampler) / in-line process. The CantyVision™ Software accurately measures multiple aspects of the JET FUEL from water/ solids / gas independent of each other for accurate data.

JET FUEL

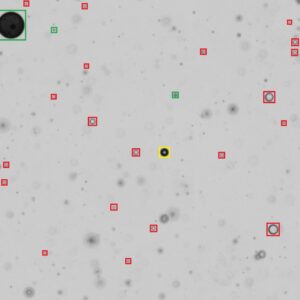

LUBE OIL ANALYSIS

Particles in lubricating and hydraulic oils are detrimental as they increase wear, clog filters, and accelerate oil degradation. Particle analysis assesses the capability of an online filtration system to clean the oil, and determines if off-line re-circulation filtration is required to clean the fluid, or whether a complete fluid change out is necessary. A high level of wear particles within the fluid is indicative of an impending component failure. Predictive maintenance by periodic lubrication oil analysis can be used to predict and prevent such failures.

LUBE OIL ANALYSIS

OIL IN WATER

CANTY specializes in OIL IN WATER monitoring. CANTY can detecting the oil droplet size as well as concentration independent of solids or gas.

OIL IN WATER

PRODUCED WATER

Canty specializes in many applications for the PRODUCED WATER industry. Some of these include concentration / particle size measurement of oil in water and solids in water.

PRODUCED WATER

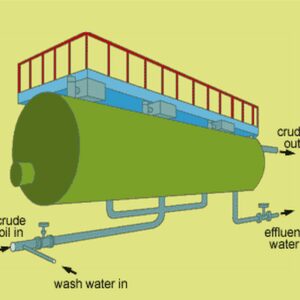

REFINERY

Canty specializes in many REFINERY applications. Some applications include oil in water / water in oil, hydrogen reformer cameras, and desalter monitors.

REFINERY

TANK FARM

Monitor phase split in batch mode on organic droplets for increased product recovery.

TANK FARM

WATER IN OIL

CANTY specializes in WATER IN OIL monitoring. CANTY can detecting the water droplet size as well as concentration independent of solids or gas.