Brewing

Canty specializes in many applications for the Brewing industry. Some applications include turbidity / color, sight glasses, and vessel lights.

BREWING

CANTY specializes in many Dairy applications. Sight Glasses, lighting, and spray dryer monitoring are among some of the applications.

DAIRY

PEELER OPTIMIZATION

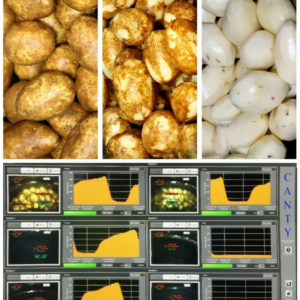

The CANTY PEELERCAM™ can be used to optimize any fruit or vegetable peeling process. Whether running a batch or continuous process, the PEELERCAM™ system can determine when the product has been suitably peeled, therefore avoiding over or under peeling, which ultimately increases product throughput while minimizing product waste.

PEELER OPTIMIZATION

In the past 100 years, potato processing has significantly evolved from largely manual labor to highly automated systems with advanced sorting and quality control mechanisms, utilizing technology like optical sorting machines to identify and remove imperfect potatoes, leading to faster, more efficient production and a wider variety of processed potato products with consistent quality.

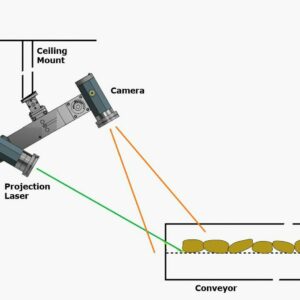

CANTY's range of dynamic imaging systems can be used to do just that, by providing unparalleled views into the process, and generating useful data that can be used for process control and optimization. Potato processes where the CANTY vision based instrumentation can be employed include Peel Measurement, Volume Flow, Size and Shape Analysis, Starch Detection and product quality control. Experience real-time decision-making that optimizes your processes while also enhancing productivity and minimizing environmental impact.

.

POTATOES

CANTY specializes in many Spray Drying applications. Sight Glasses, lighting, and turbidity are among some of the applications.

SPRAY DRYING

While the basics of mass sugar refining have not changed significantly in the last 200 years, it is important to take advantage of relatively newer technology to allow the production processes to run more efficiently and produce a higher yield. CANTY's range of dynamic imaging systems can be used to do just that, by providing unparalleled views into the process, and generating useful data that can be used for process control and optimization. Sugar production processes where this technology can be employed include clarifying, crystallization, centrifuging, and product quality control.