Using image analysis CANTY can track the position of rebar with accuracy to within 1/2”.

REBAR

MOLTEN LEVEL

Canty specializes in many MOLTEN LEVEL application. Using an Ethernet CCD camera real time level is controled giving visual verification.

MOLTEN LEVEL

SLAG MONITORING

Canty specializes in SLAG MONITORING using ethernet CCD cameras to easily detect when slag occurs and alarms so the slag can be removed.

SLAG MONITORING

POWDER METAL PROCCESSING

Canty specializes in many applications in POWDER METAL plants. Some of these include partcile size analysis & high temperature cameras to monitor the pour.

POWDER METAL PROCESSING

HOT RAIL LENGTH

Canty specializes in montoring HOT RAIL LENGTH. Using an Ethernet CCD camera the rail lenght / thickness / and temperature can all be monitored real time from one device.

HOT RAIL LENGTH

FURNACE MONITORING

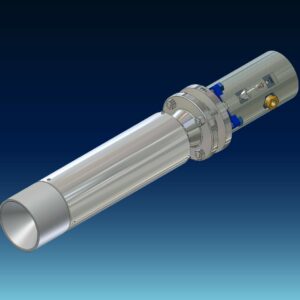

Canty specializes in monitoring furnaces using HIGH TEMPERATURE CAMERAS.

FURNACE MONITORING

TEMPERATURE

Canty specializes in many TEMPERATURE applications in foundries and metal production. Some of these include flame control and metal temperature measurement above 750F.

TEMPERATURE MEASUREMENT

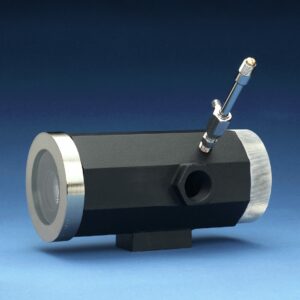

SURVEILLANCE CAMERAS

Canty specializes SURVEILLANCE CAMERAS for foundries. Using the patented spray ring the camera requires no maintenance to keep it clean.

SURVEILLANCE CAMERAS

CONTINUOUS GALVANIZING

A continuous galvanizing line (CGL) restores the mechanical properties of the cold rolled steel by heating the strip up to temperature then applying a metallic coating to it’s surface by dipping into a molten bath of Zinc/Aluminum. This improves the corrosion resistance of the steel strip. Using image analysis with the CANTY Ultratemp Camera and Intelligent machine learning software, the position of the strip on the rollers can be tracked to prevent process upsets such as strip tearing while also allowing for visual verification form the operator. Control signals are output to the DCS via 4-20mA, Modbus TCP/IP or OPC UA.