FLOAT GLASS

Canty specializes in many applications in FLOAT GLASS. Some of these include molten glass level and width / knurl detection.

FLOAT GLASS

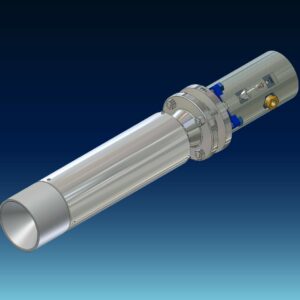

MOLTEN GLASS LEVEL

The CANTY Molten Glass Level system consists of a high temperature surveillance camera, mounted to view the surface of the molten glass through an opening in the wall. On the wall directly opposite the camera, a reference point is created, often by simply removing a brick from the wall, or boring a hole though it. The position of the reflection of this reference point on the surface of the glass relative to the fixed mount camera, is directly related to the molten glass level. CantyVision™ software is configured to track the position of this reflection with accuracy to 0.001” (0.025mm). A cross-hair is displayed on the operator screen image at all times, to allow the user to visually verify what point is begin tracked by the software. Control outputs are available to the DCS via OPC, 4-20mA and Modbus TCP/IP.

MOLTEN GLASS LEVEL

GLASS BOTTLE

Canty specializes in many applications in GLASS BOTTLE plants. Some of these include gob and temperature detection.

GLASS BOTTLE

FIBER GLASS

Canty specializes in many applications in FIBER GLASS. Some of these include stream flow control and width detection.

FIBER GLASS

GLASS BEAD

CANTY specializes in the particle size and shape measurement of glass beads manufacturing.

GLASS BEAD

HIGH TEMPERATURE CAMERAS

Canty specializes in many HIGH TEMPERATURE CAMERA applications in the glass industry. Some of these include flame control and batch monitoring.