CENTRIFUGE

CANTY centrifuge control analzies fill level, filtering level, and a separate cake (solids) detection signal. The level control allows for consistent batching to the centrifuge. The cake detection 4-20mA output signal provides for immediate detection of solids, which prevent the cake from cracking. This means higher product yield due to fewer washes, and ultimately better product quality.

CENTRIFUGE

LAB CRYSTALLIZER - GLASS REACTOR

Seed control is easily obtained by the CANTY Glass Reactor Microscope provides a unique microscopy system that can be calibrated in situ down to .3um (.7um vis). It provides stunning 2D size and shape analysis, concentration measurement, and visual verification in a single instrument. Compared to other technologies, the CANTY Glass Reactor Microscope is more practical as it does not require multiple probes to measure random cord length. It provides 2D results in the best possible resolution via CANTYVISION Software. The CANTY Glass Reactor Microscope provides data in compliance to the ASTM E29 and ISO standards and readily correlates to other PSM systems.

LAB CRYSTALLIZER - GLASS REACTOR

FILTER DRYER / NUTSCHE

Stop washing product away! Monitoring the entire filter drying process will yield higher production results. Using the CANTY light and FuseView will assist operators looking into the dryer by using the brightest net light output on the largest view. The CANTY camera and light combo can be used to control and monitor level control and cake detection. By using the CANTY system it will eliminate over drying of the cake.

FILTER DRYER / NUTSCHE

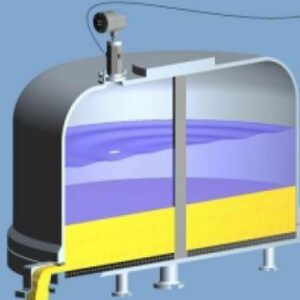

FOAM & LEVEL DETECTION

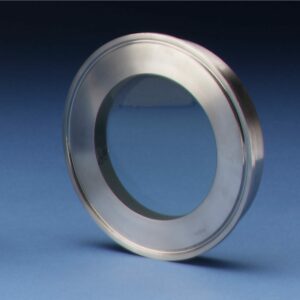

CANTY Camera & Light Vision Systems are a patented design to view and illuminate the inside of a pressure or process vessel through a single connection. There is no need for multiple ports! CANTY can supply an integrally mounted camera and light (optional) in flanged, sanitary or NPT threaded process connections. CANTY fused glass technology provides a safe, high pressure, hermetic fused glass barrier between the process and the camera electronics.

FOAM & LEVEL DETECTION

PARTICLE ANALYSIS

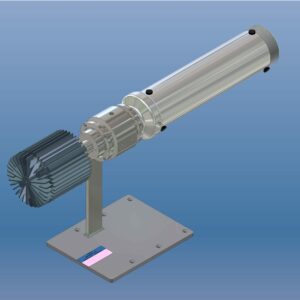

Canty’s Mini Inflow product line can be set up in a variety of configurations to be used anywhere within a pharmaceutical process in order to ensure that processes are running at their maximum efficiency and to bring awareness to process upset conditions in real-time.

Canty mini Inflow analyzers utilize the latest in visible-spectrum microscopic imaging technology. Canty’s Gigabit Ethernet cameras, microscopic lenses, trademark fused glass, LED cool lighting systems, and proprietary CANTYVISION Intelligent Analysis software combine to provide the very best in real time analysis of particle concentration and size and shape distributions

PARTICLE ANALYSIS

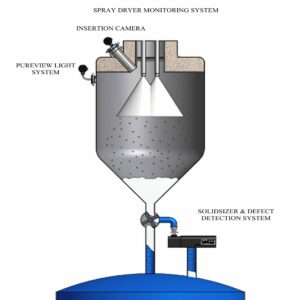

SPRAY DRYER

Monitoring the entire spray drying process will yield high production results. To start by monitoring the turbidity of the liquid going into the dryer will help decrease buildup on the nozzel or imperfections. Using the CANTY light and FuseView will assist on looking into the actual dryer. The CANTY camera and light combo can be used to control and monitor the angle of which the spray comes out of the nozzle. Finally, at the end the SolidSizer with color spec can make sure the particle size is correct and no impurities are forming online.

SPRAY DRYER

VOLUME FLOW

The CANTY SolidSizer™ is a vision-based sensor used with the CANTY Vector System image processor for dry particle size measurement in a laboratory environment.

VOLUME FLOW

The Canty PHARMAFLOW™ provides non-destructive microscopic viewing and delivers particle size analysis with two-dimensional results when used alongside the CantyVisionClient™ Software.