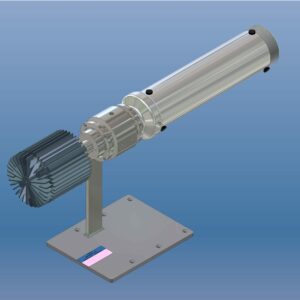

CENTRIFUGE CAMERA CONTROL

A camera light combination system is mounted to the centrifuge using the CANTY angled mounting plate. This allows for continuous monitoring from the control room, of initial product filling, the various washing and spinning cycles, and product discharge, therefore enabling greater operator control and efficient identification of any process issues. In the control room, the Vector™ image processing computer will analyze this view and provide a 4-20mA or OPC output of fill level, filtering level, and a separate cake (solids) detection signal. The level control allows for consistent batching to the centrifuge. The cake detection 4-20mA or OPC output signal provides for immediate detection of solids, which prevent the cake from cracking. This means higher product yield due to fewer washes, and ultimately better product quality.

- Cake Thickness

- Color Line Control

- Wash Optimization