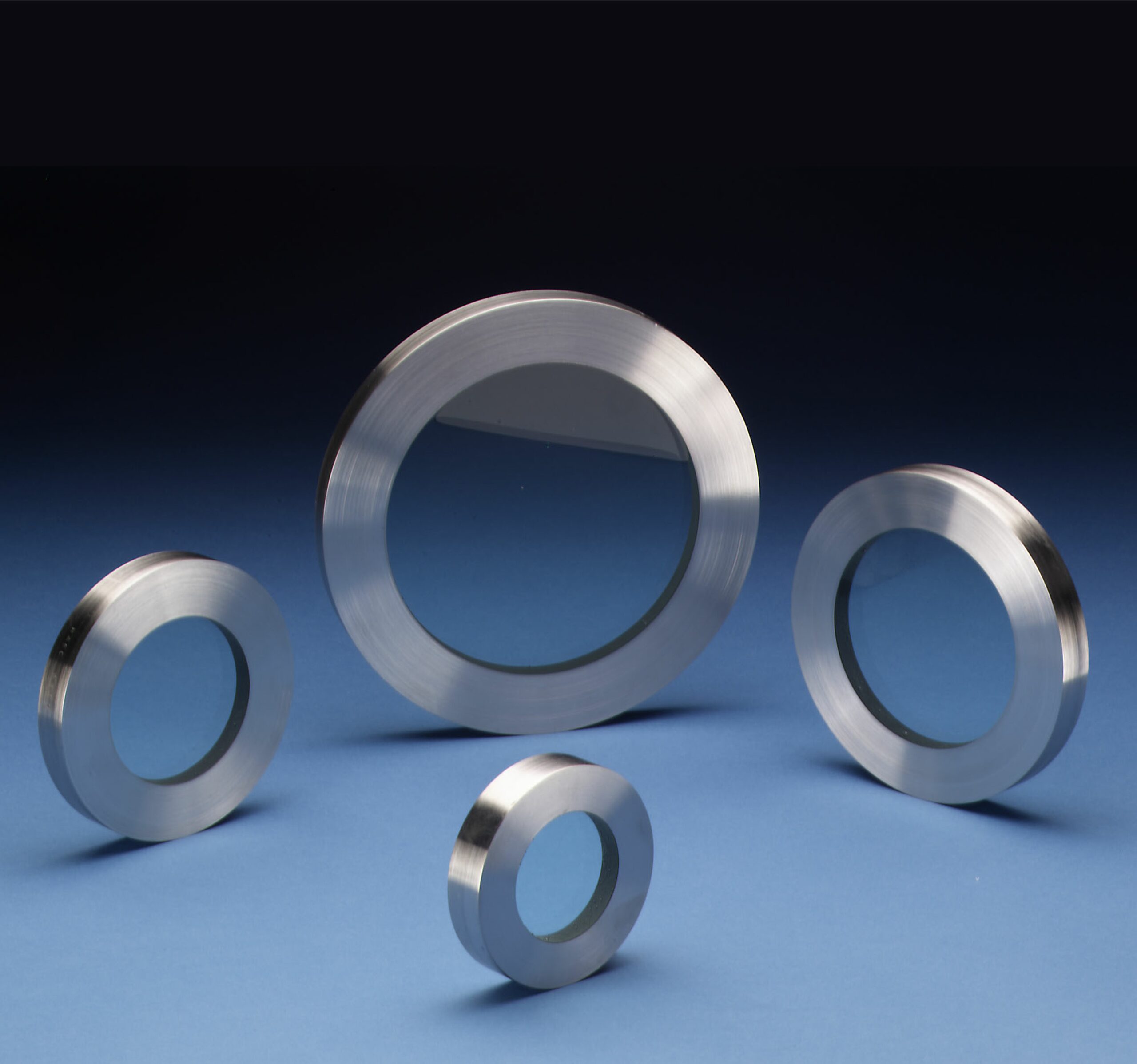

Sugar Pan – Fuseview™

The Fuseview™ eliminates the chance of glass getting into the evaporators or sugar pans by over torque of the operators. Also, it allows for the sugar pan to pull full vacuum unlike tempered glass.

Product Description

- ROI = 1 CENT / DEGREE (F) / GALLON

- Allows evaporator to pull full vacuum

- May be removed for cleaning and inspection and then placed back on evaporators unlike tempered glass

Metric Units:

To heat 1 litre (1 kg) of water from ambient 20°C to a boiling point of 61°C (dependent on vacuum level)

Q=mCp(T2-T1)

Q = energy required (kJ), m = mass (kg), Cp = specific heat (KJ/kg°C – value for water (4.186) assumed), T1 = starting temperature °C T2 = finishing temperature °C

Q=1(4.186)(61-20)

Q=171.62kJ / 0.0477kWh per litre

2014 US energy prices had electricity at 10c per kWh, giving a cost of 0.477c per litre

To heat 1 litre (1kg) of water from ambient 20°C to a boiling point of 60°C (dependent on vacuum level)

Q=mCp(T2-T1)

Q = energy required (kJ), m = mass (kg), Cp = specific heat (KJ/kg°C – value for water assumed), T1 = starting temperature °C, T2 = finishing temperature °C

Q=1(4.186)(60-20)

Q=167.44kJ / 0.0465kWh per litre

2014 US energy prices had electricity at 10c per kWh, giving a cost of 0.465c per litre

Difference is 0.477 – 0.465 = 0.012c per litre per degree C (1c per 83 litres per degree C)

Capacity of Crystal Pan (litres) = Saving per Batch per Degree Celcius (USD $)

25,000 = $3.00

50,000 = $6.00

100,000 = $12.00

Imperial Units:

To heat 1 US gallon (8.34 lbs) of water from ambient 68°F to a boiling point of 141°F (dependent on vacuum level)

Q=mCp(T2-T1)

Q = energy required (BTU), m = mass (lbs), Cp = specific heat (Btu/lb°F – value for water (1) assumed), T1 = starting temperature °F, T2 = finishing temperature °F

Q=8.34(1)(141-68)

Q=608.82BTU / 0.178kWh per gallon

2014 US energy prices had electricity at 10c per kWh, giving a cost of 1.78c per gallon

To heat 1 US gallon (8.34 lbs) of water from ambient 68°F to a boiling point of 140°F (dependent on vacuum level)

Q=mCp(T2-T1)

Q = energy required (BTU), m = mass (lbs), Cp = specific heat (Btu/lb°F – value for water (1) assumed), T1 = starting temperature °F, T2 = finishing temperature °F

Q=8.34(1)(140-68)

Q=600.48BTU / 0.176kWh per litre

2014 US energy prices had electricity at 10c per kWh, giving a cost of 1.76c per gallon

Difference is 1.78 – 1.76 – 0.02c per gallon per degree F (1c per 50 gallons per degree F)

Capacity of Crystal Pan (gallons) = Saving per Batch per Degree Fahrenheit (USD $)

7,500 = $1.50

15,000 = $3.00

30,000 = $6.00