LIME KILN

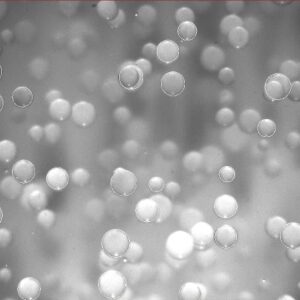

A LIME KILN is used to produce quicklime by the calcination of limestone that is calcium carbonate. The rotary kiln that is used operates around 900°C-1000°C. This operation needs to be monitored and reported on to make sure the producers are making good usable product. If the product does not reach the required state to make the chemical reaction then is just stays as limestone. If the kiln over heats it will start to make unusable burnt product.

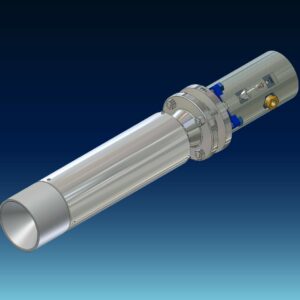

A key feature that must be maintained is the fire in which they are using to cause the calcination of the material. This can be achieved by monitoring the fire by its temperature. Another key item to monitor on the fire is its size and shape to make sure the kiln is having uniform heating. CANTYVISION can be used to monitor the temperature of the flame and also give visual verification of size. The rotation of the kiln plays a key role in making sure the product is distributed correctly and that the product is not creeping up the side walls too high or too low as that will affect the rate at which the limestone is heating up and ultimately affect the calcination process. CANTYVISION can be used to give visual verification of product. This will be a critical feature for the operator.

Product Description

- Flame Temperature

- Bed Level

- Bed Temperature

- Wall Temperature