HOW VISION SYSTEMS WORK

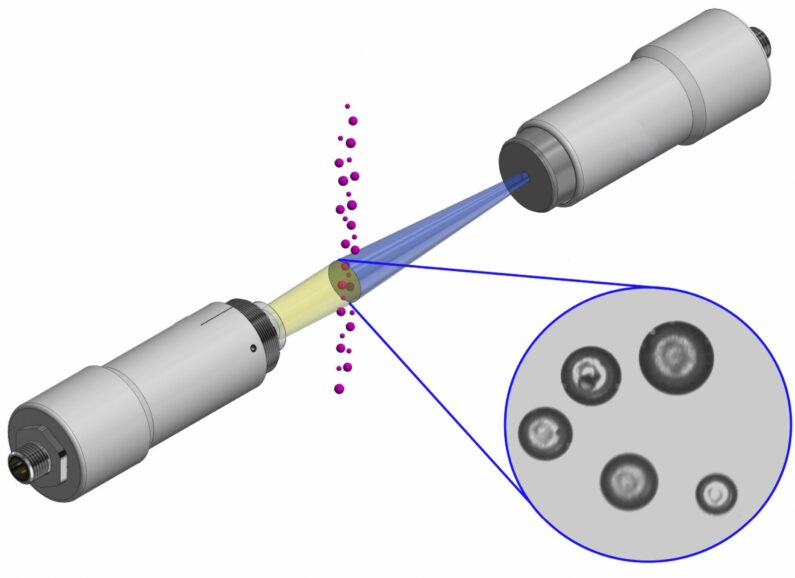

Vision systems measure particle size and shape by passing particles or fluids between camera optics and a light source. Images of the material are brought into CANTY’s particle sizing software and analyzed to measure over 40 different size and shape factors for every particle seen. The differences in shape allow for the software to differentiate between different kinds of particles such droplets, bubbles, and solids as well as differences within each of those group. If there is a morphological difference between materials, CANTY can tell the difference. Knowing the type of particle, size, and shape allows the software to generate particle size distributions, counts, and concentrations of all of these things independent from one another, but at the same time. While other analyzers require blind trust in the measurement, CANTY’s vision systems have the ability to record videos during analysis, providing visual verification of all measurements made.

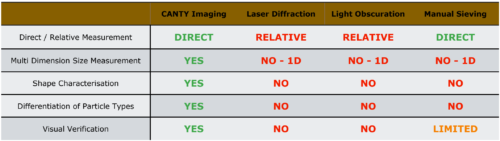

COMPARISON WITH OTHER TECHNOLOGIES:

Other technologies on the market for particle sizing include sieve stacks, laser diffraction, and light obscuration. While these technologies provide some information, they each have major pitfalls that make vision systems the best technology for the job. See the below chart that explores the differences between these technologies:

For additional information, read through our guide in choosing a particle analyzer found in the Product Documents section of this page!